Our team is innovative at heart. We work with the latest emerging technologies to provide you with the competitive advantage in the marketplace.

Technology Philosophy and Approach

It's simple - we believe in empowering our clients with innovative technology to help make a positive impact in their business and life.

With the ever-increasing spread of information, technology is evolving more and more rapidly. We work hard to maintain our position as one of the leaders in the field of hi-tech electronic design and strive to make best use of technology for both our own business and our clients' products.

Whether you want to develop a completely new product or apply a new feature to an existing one, we can help you achieve and maintain a competitive advantage in the marketplace through designing your product with the latest emerging technology in mind.

Beta Solutions' Technology Resources:

Laboratory Design and Test Equipment

Prototyping, quality control, fault diagnosis and repair, all require a wide range of laboratory equipment. The below lists of equipment are just some of what we have and use everyday.

Power Supply and Analysis

The ability to power a device or prototype circuit is crucial in the laboratory. To power a wide range of devices safely, we use power supplies with advanced features, such as; current limiting, isolated grounds, fine-tuned voltages, and/or AC power. Sometimes, it is worth testing devices beyond their normal operating parameters, which is where surge testing is used.

Load testing is important in verifying on-board power supplies, as well as battery or super-capacitor circuit testing.

Our power supply and analysis equipment include:

- Programmable DC Power Supplies

- Benchtop Digital Multimeter

- Electronic Load

- Programmable AC Power Source

- Handheld LCR Meter

- Multi Powered Fence Energizer (Surge Testing)

Environment Analysis

It's not always about electronics; often a prototype or device will interact with the world via light, sound, heat, pressure, etc. Sensors and generators in these fields are vital equipment. Heat sensing, either via a thermocouple or thermal imaging, is very useful in confirming thermal calculations or fault detection on circuit boards.

Our signal analysis equipment includes:

- 1GHz Mixed Domain Oscilloscope

- 2GHz Spectrum Analyzer

- Handheld RF Vector Network Analyzer

- Function/Arbitrary Waveform Generators

Fabrication Equipment

This equipment gives us the ability to build prototypes for new designs or new iterations, as well as small-scale production.

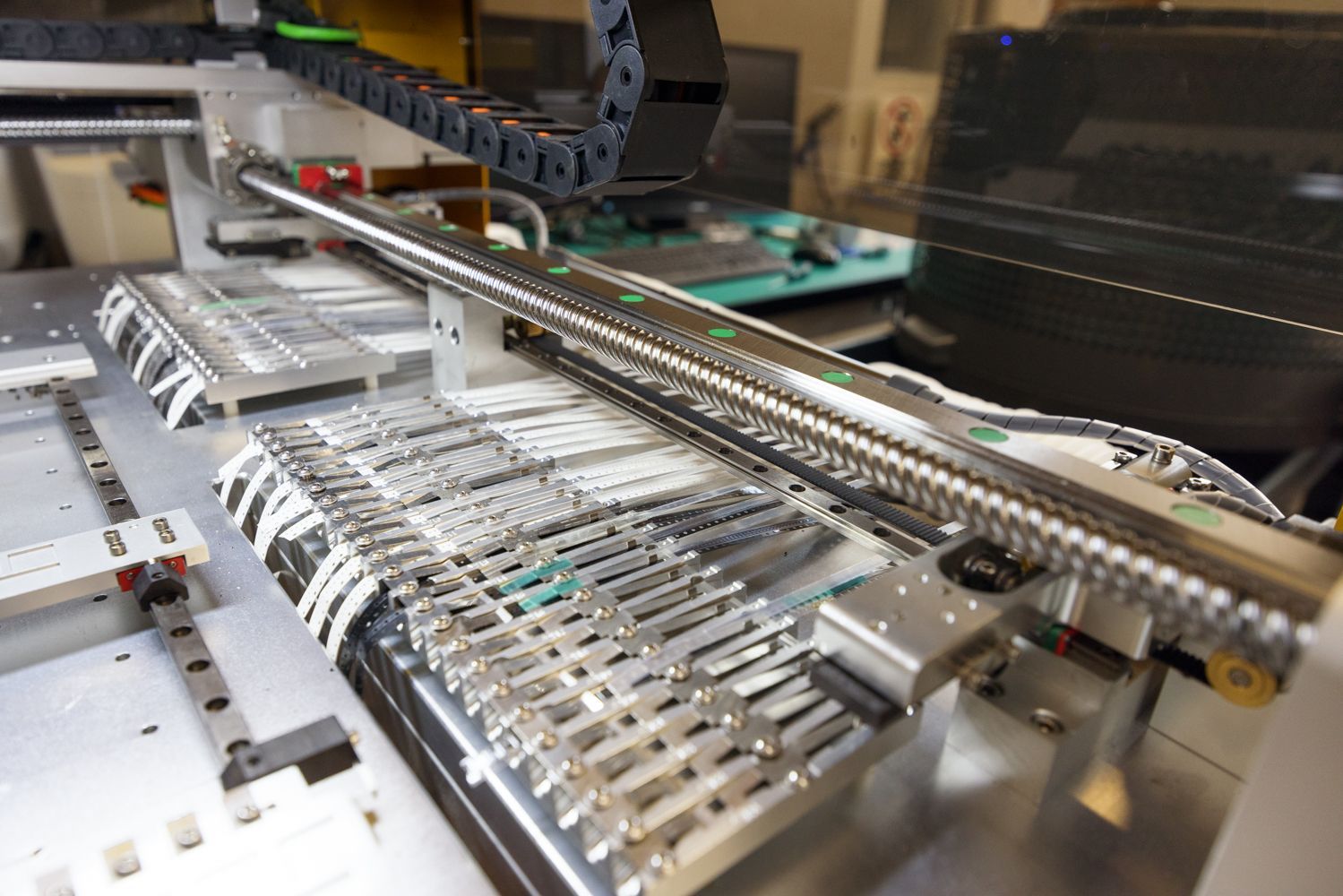

PCBA involves procuring manufactured PCBs according to design. Applying solder paste (a consumable material) using a PCB Stencil in a Stencil Printer. Surface mount device(SMD) components are placed on the PCB in the wet solder paste with a Pick and Place machine. The populated board is then placed into the reflow oven for soldering. Through hole components are then soldered on by hand with a soldering iron. The completed PCB is often given a bath in an ultrasonic cleaner to clean any residue flux. Finally, the board runs through the quality control process, which is different for every project.

PCBA

3D printing allows us to rapidly prototype physical components of electronic design, be it the outer housing or any other small mechanical components.

- Stencil Printer

- Manual Pick & Place

- Automated Pick and Place Machine

- Reflow Oven

- Soldering Stations

- Hot Air Rework Stations

- Digital Ultrasonic Cleaner 10L

- Anti-static mats

- Rework heated bed

Design Software and Tools

We use professional software to produce professional results. Not only does it provide the ability to create high quality output, but it also allows for collaborative workflows, greatly improving efficiency.

Hardware Design Tools

- Altium Designer (latest version), schematic and PCB Design

- Altium 365, online tools

- Solidworks (latest version), 3D Mechanical Design

Simulation

- LTSpice, circuit simulator

- Scilab, mathematics scripting

- Saturn PCB Design Toolkit, circuit calculator

Firmware Development

PsoC Creator

- Visual Studio Code

- Microchip/Atmel Studio

- Silicon Labs Simplicity Studio

- Texas Code Composer Studio

- Microchip MPLab Microcontroller IDE

- Arduino IDE

Operating Systems

- Linux

- QP

- FreeRTOS

- Zephyr

Often used microcontroller families

- Infineon (PSoC 4, PSoC 5, PSoC 6)

- Nordic Semiconductor (nRF52, nRF91)

- EspressIf (ESP32)

- Microchip (PIC32)

- Arduino

- Raspberry Pi

- Silicon Labs (Blue Gecko)

Software Development

- Visual Studio

- PyCharm

- IntelliJ

- Labview

Cloud Based Tools

- Amazon Web Services (AWS)

- Memfault

- Particle Cloud

- Node-RED

FPGA Development

- Xilinx Vivado

- Xilinx SDK FPGA Software Development Kit

- PetaLinux

Primary Coding Languages

- C, C++, C#

- Java, JavaScript

- Python

- VHDL

- Perl

- Ruby

Documentation and Management Tools

- Google Workspace

- WorkflowMax: Project Management Software

- Atlassian Trello, Confluence, & Jira

- GitKraken and GitLab

- Slack

Beta Solutions Project Showcase

Touch Screen Fume Cupboard Controller.

The project's continued success reaffirms our commitment to devise winning solutions in collaboration with our clients.

"I would like to thank Beta solutions for being great to work with and delivering us a very sophisticated, high quality and good value solution for our customers."

Andy Gow Thermoplastic Engineering Ltd (TPE)

Have you got an idea and need help to take the next step?