mmWave Radar Sensor

Introduction

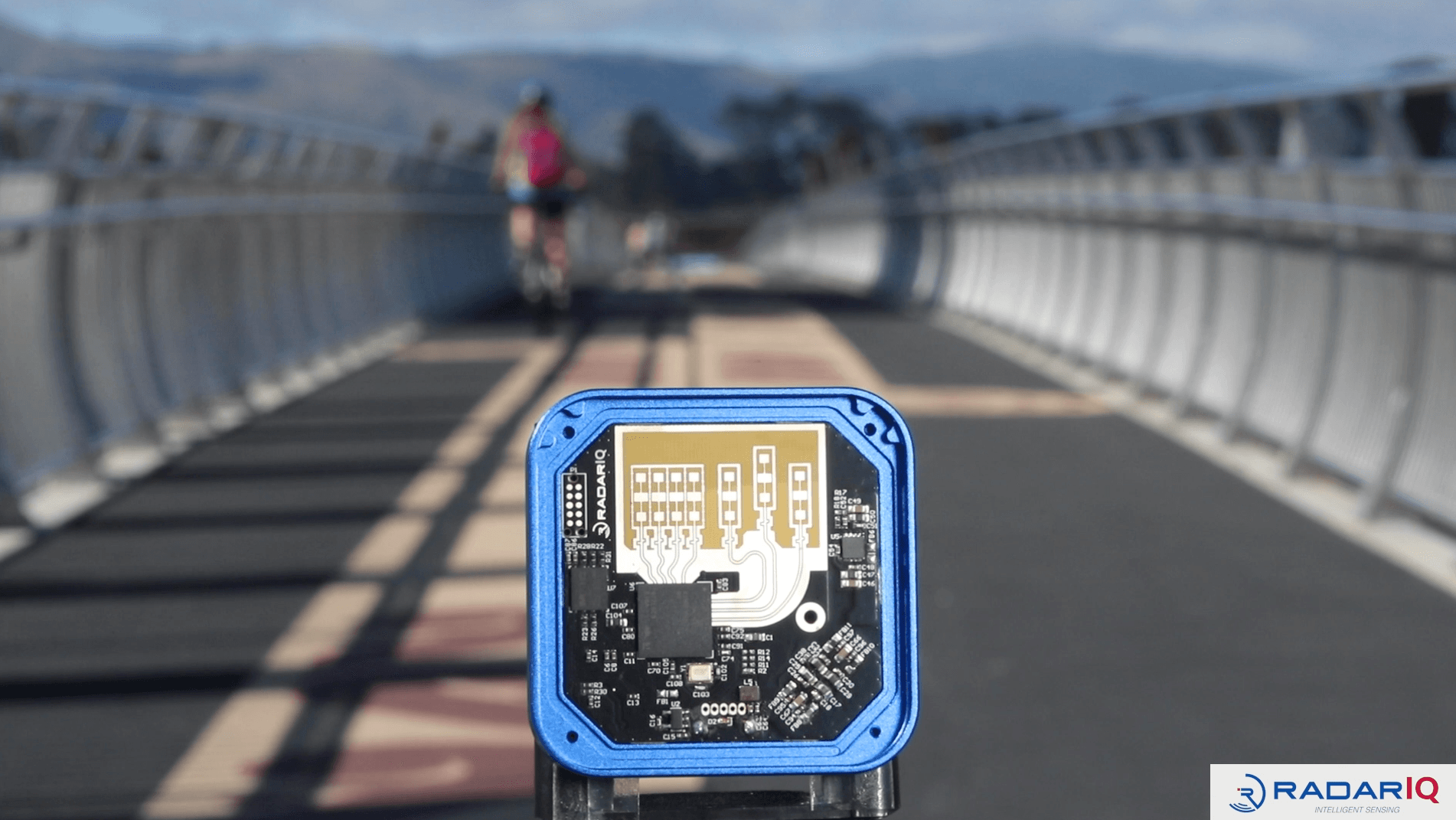

Radar is a detection system that uses radio waves to determine the position and velocity of objects. Radar is difficult and expensive for everyday makers and engineers to engage with, and thus far has been the domain of specialist engineers and the automotive industry. RadarIQ, a startup who successfully launched on Kickstarter in 2021, design specialist radar sensors that are uniquely able to accurately measure speed, movement, and distance. Its sensors make object detection easier than ever, unlocking the potential of mmRadar technology for all by creating accessible, easy to use products.

RadarIQ engaged Beta Solutions to design a product that makers and robotics enthusiasts could easily use, when developing their own object tracking and radar-vision based applications. The brief was to design and build a specialist fmcw - mmWave radar sensor into a form-factor, which is attractive and suitable for the maker and light engineering market. As well as designing the electronics enclosure, we also had to create the ‘easy to use’ firmware for the sensor.

This project involved high-speed PCB design, RF simulation, mechanical design, embedded firmware and software development.

In addition to the required new product R&D, RadarIQ engaged the Beta Solutions team to completely facilitate the entire manufacturing process (on an on-going basis) for its electronic products - thereby acting as a "one-stop-shop".

The Solution and Product

Designing the product required us to use a cutting edge mmwave radar technology, and a number of unique design elements with their own subset of requirements. These were:

- mmWave radar aspects

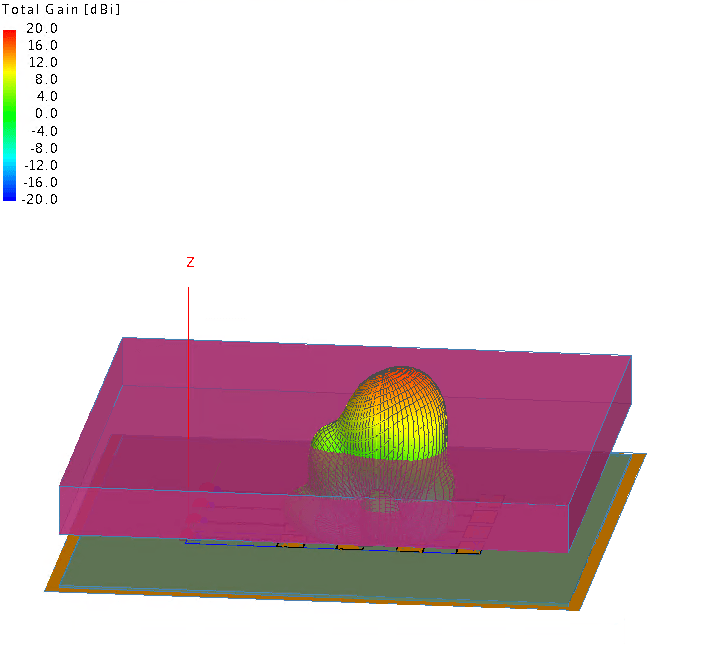

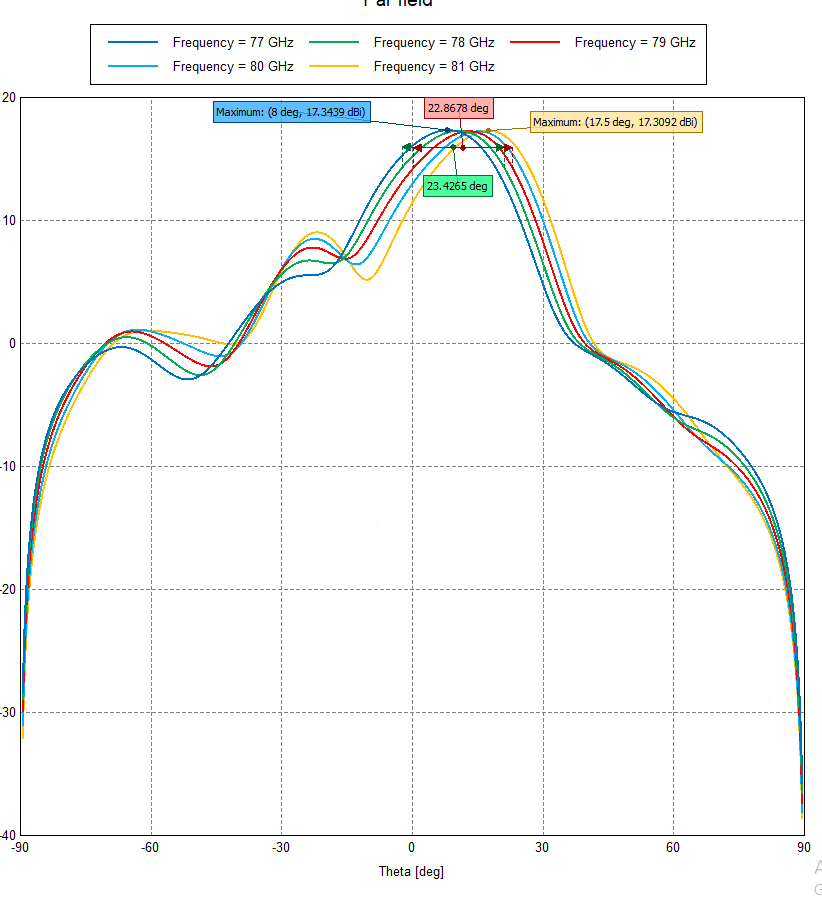

Requiring the following: - mmWave multiple input, multiple output (MIMO) antenna simulation.

- Design of the plastic enclosure that does not distort the radar signals, which uses specialty radar plastics for the injection mould.

- Significant amount of regulatory certification testing and verification.

- Production testing setup to verify the radar signal on all units for quality control.

- Production testing of the quality of the data that was returned.

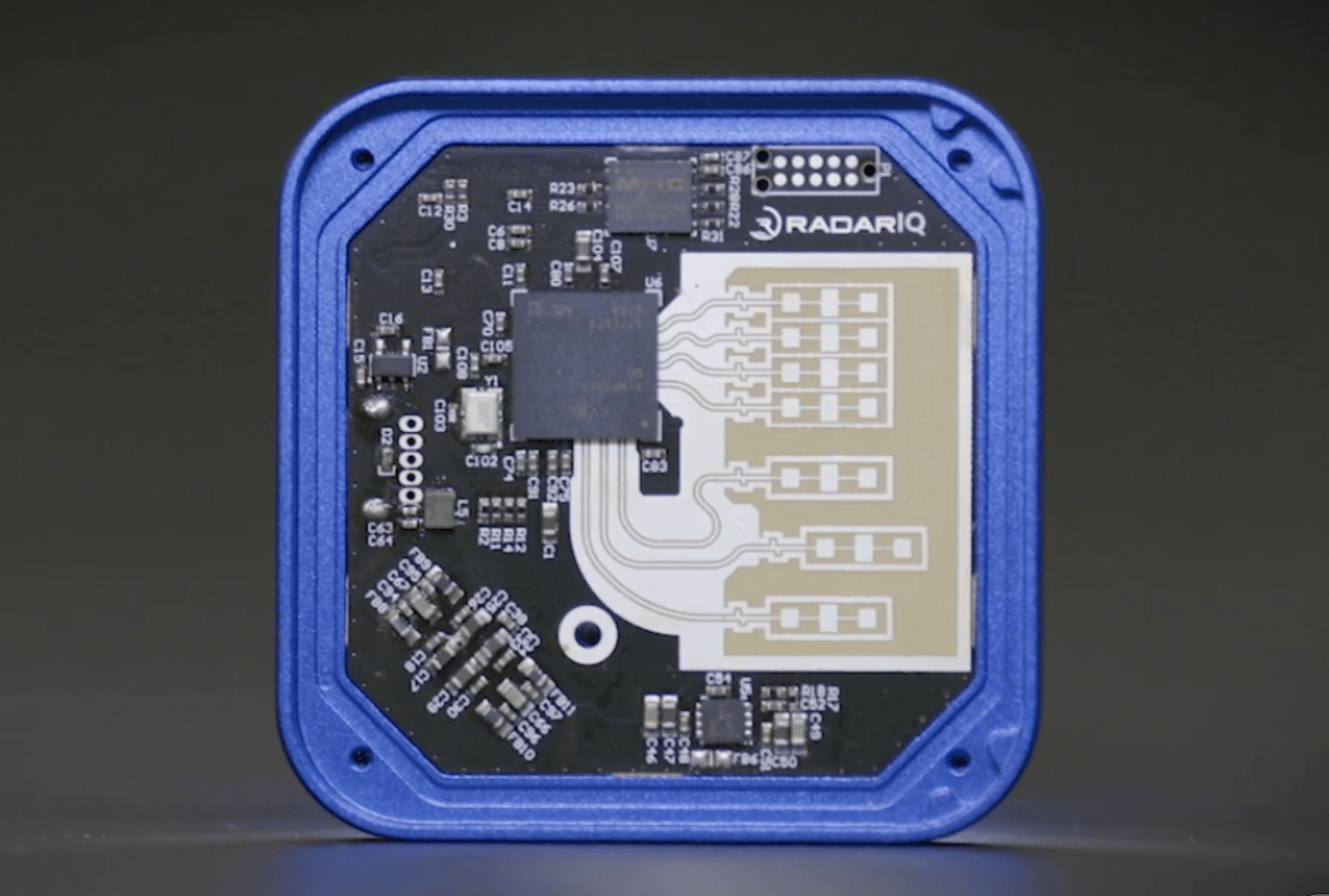

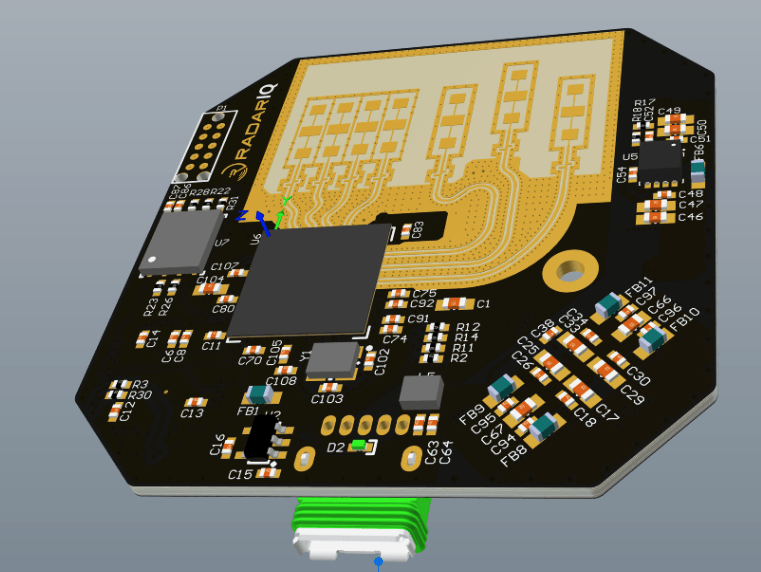

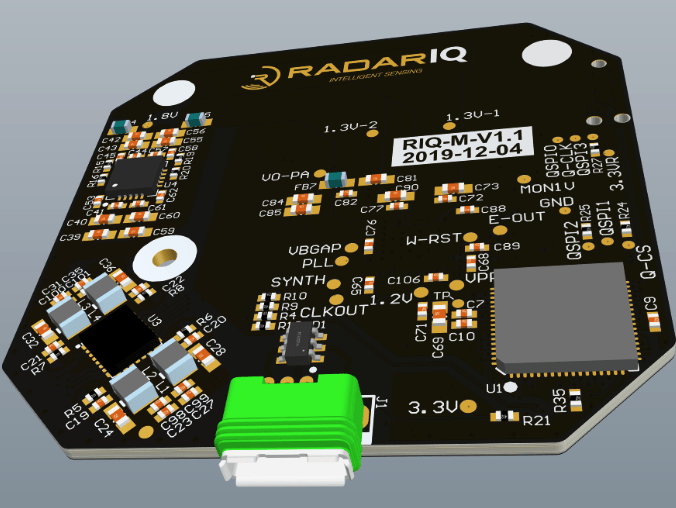

- PCB design

The design incorporated the following: - High frequency GHz speciality rogers PCB materials.

- Low noise power supply design with approximately 9 different supply rails requiring different voltage and startup requirements.

- Cost minimisation.

- Design for Manufacturing, so that it can be manufactured in acceptable timeframes.

- Mechanical design

The design incorporated the following: - Quality machined aluminium anodised enclosure.

- Injection-moulded top with specialist radar plastic.

- Water ingress testing.

- USB connector.

- Firmware Design

The design included the following: - Multi processor bootloader to allow the reprogramming of multiple processors via the same interface.

- Enabling of USB and serial over the same USB connection.

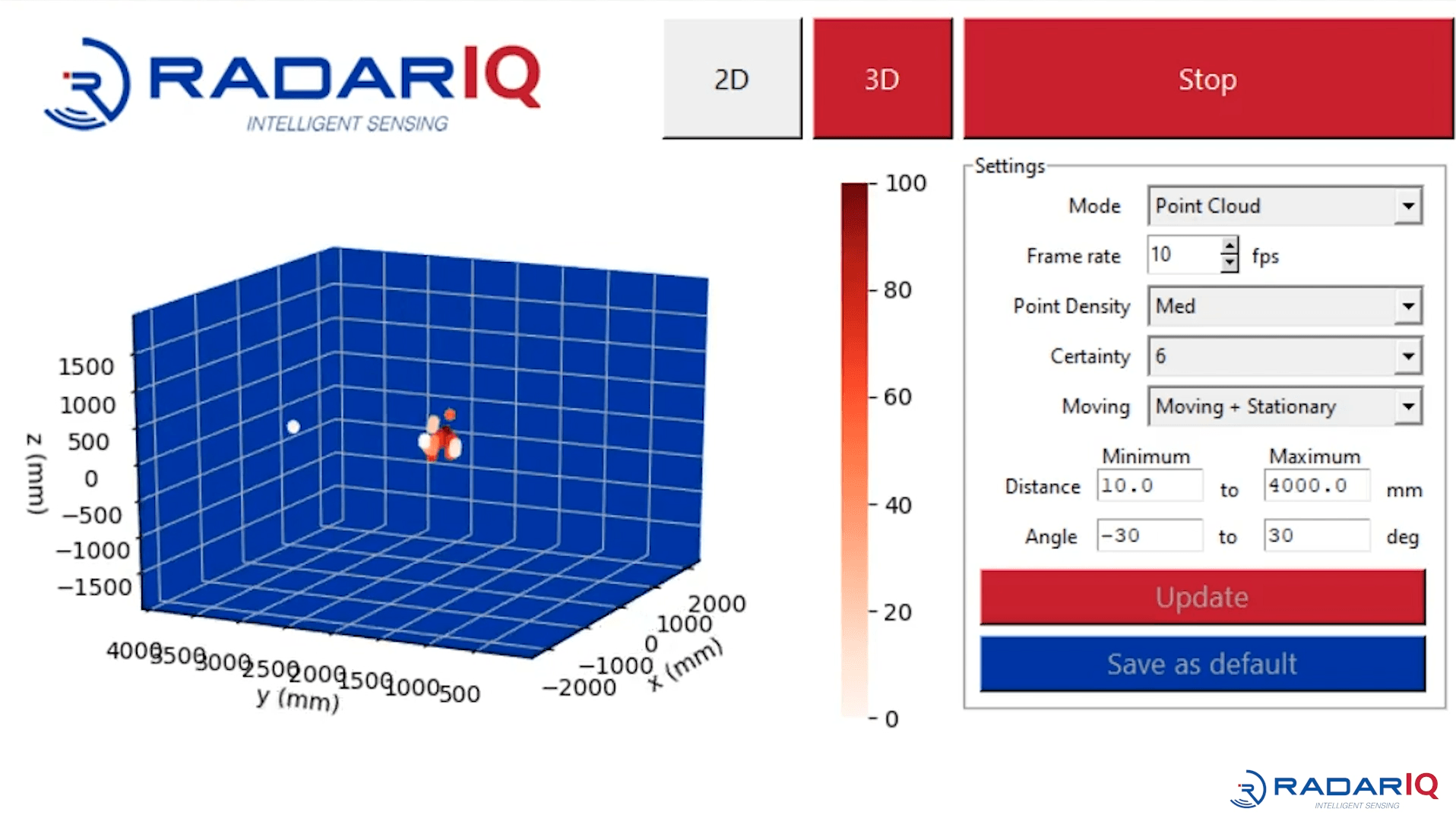

- Significant levels of signal processing - understanding and processing of the radar signals, involving 3 dimensions of FFTs (fast fourier transforms).

- Developing a publicly available library https://github.com/radariq/arduino-library, in order for the design to be compatible with Ardiunos.

- Software design and APIs

We assisted RadarIQ’s development of the software, incorporating the following: - A Python library (https://github.com/radariq/python-sdk) with demos included.

- ROS (Robot OS) support.

- An example multi platform (windows, MacOS, and Linux) controller software created, in conjunction with RadarIQ, for easy visualization of the product.

https://radariq.io/pages/getting-started

- Marketing

We worked with RadarIQ to help with information used on marketing material, packaging and on instructions for its product.

Success

RadarIQ launched a successful kickstarter campaign in 2021, delivered product in 2022, and is now ramping up production quantities.

“Designing mmWave Radar sensors is extremely technically demanding and well beyond the requirements of most electronics projects. Beta Solutions was able to use their knowledge and skills to engineer the sensors to the demanding specifications and create a really great product. Partnering with Beta Solutions for production also took the headaches of getting quality product produced. We are really happy with our experiences with Beta Solutions.” -

Aaron Fulton (CEO)