Our Facilities

Discover a collaborative space that combines heritage and high-tech to facilitate electronic product design.

Facilities

View our facilities

Discover a collaborative space that combines heritage and high-tech to facilitate innovative electronic product design. Located in the heart of Palmerston North, Beta Solutions’ bespoke office enables creative thinking, leading R&D and a strong company culture.

Beta Solutions is located near the centre of Palmerston North’s CBD on the corner of The Square and Broadway Avenue. Our custom-designed office is rich in historical heritage and dates back to 1925. You are welcome to drop by and see what our team is up to.

Welcome to Beta Solutions! Our collaborative open spaces are designed to be not only functional and professional, but also an enjoyable and welcoming place for our team and clients.

Custom electronics circuit design is one of our core specialist services. Our electronic engineers utilise the very latest leading electronic CAD software - Altium Designer. This allows us to incorporate the electronics schematics (blue prints), circuit board layouts, and component databases, all within one professional design environment.

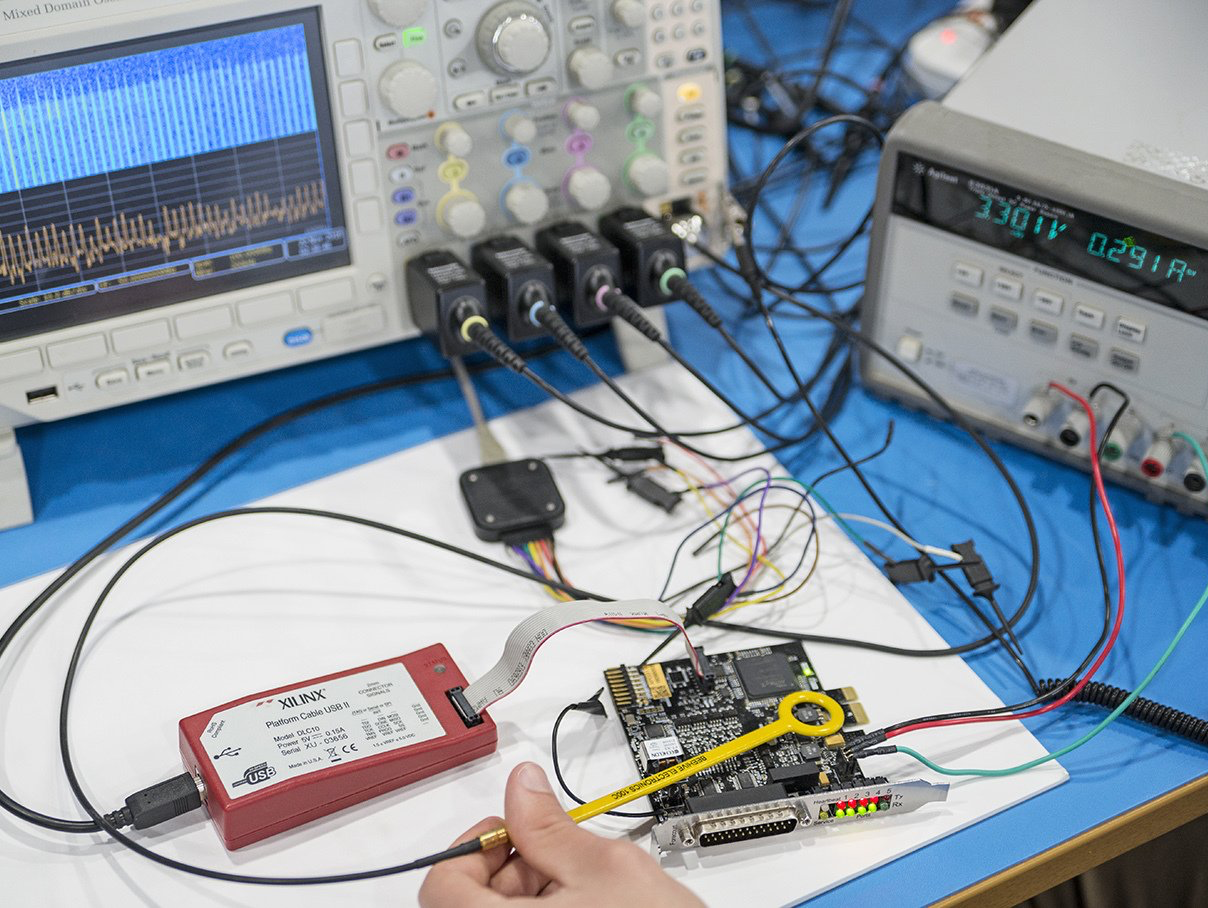

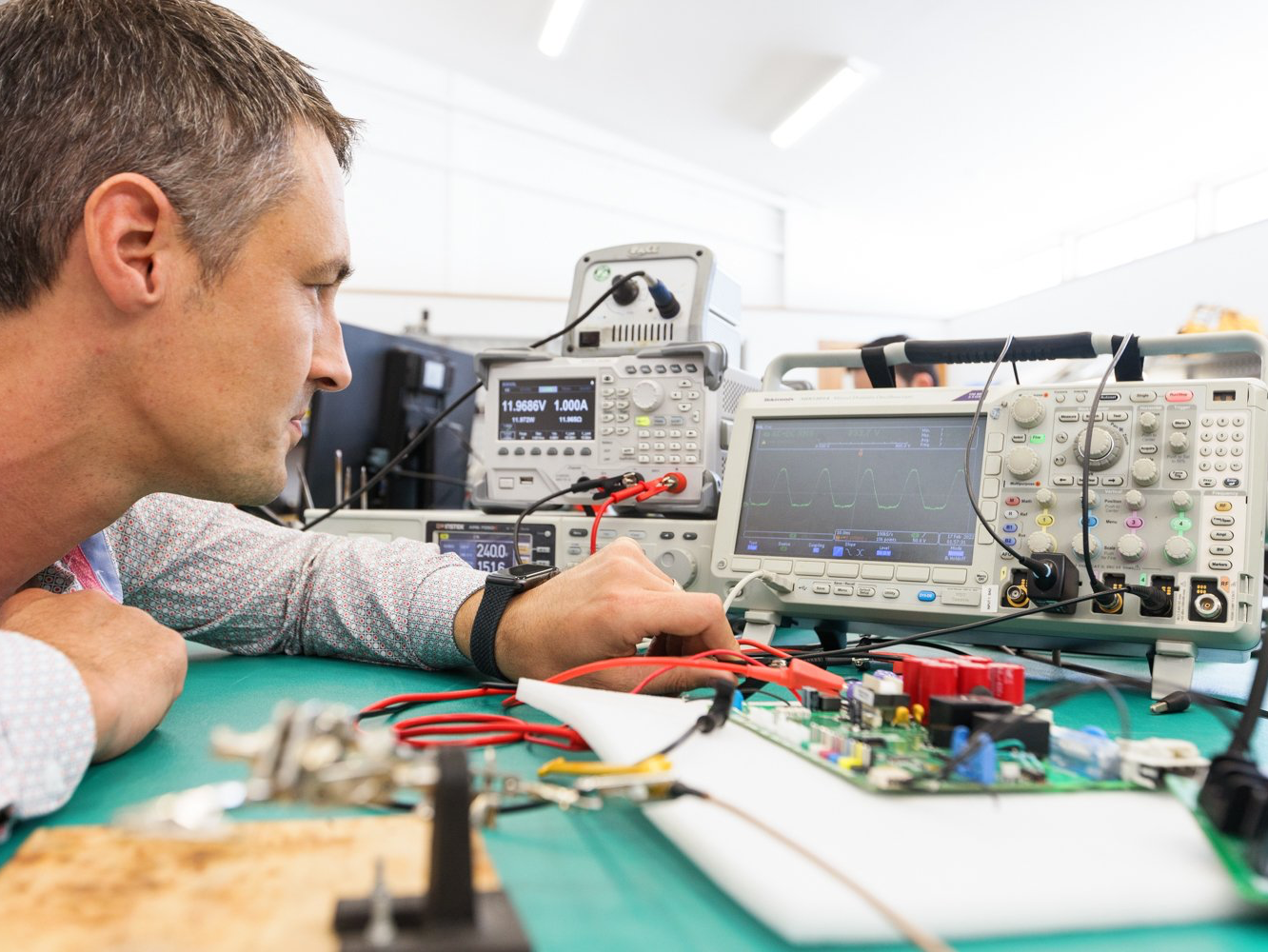

Following the design of a prototype, the next step is to undertake a rigorous "design validation". This testing ensures reliable products are delivered to our clients. Our testing equipment includes oscilloscopes, spectrum & network analysers, digital multi-meters and dedicated logic analysers.

Embedded firmware is the "software brains" designed to control a specific piece of electronics hardware, and for new products, firmware and hardware are often designed concurrently. Our software engineers use the latest technology and proven coding techniques, to ensure the final firmware is clean and reliable.

Our in-house mechanical design capability ensures our clients get a complete all-in-one service, with tight integration between the mechanical and electronics hardware. Design technology we use includes the latest Solidworks CAD software, which enables us to perform materials analysis, create 3D models, as well as 2D manufacturing-ready engineering drawings.

Beta Solutions engineers often collaborate between electronic, mechanical, firmware and software disciplines, to achieve a fully integrated end-to-end system design.

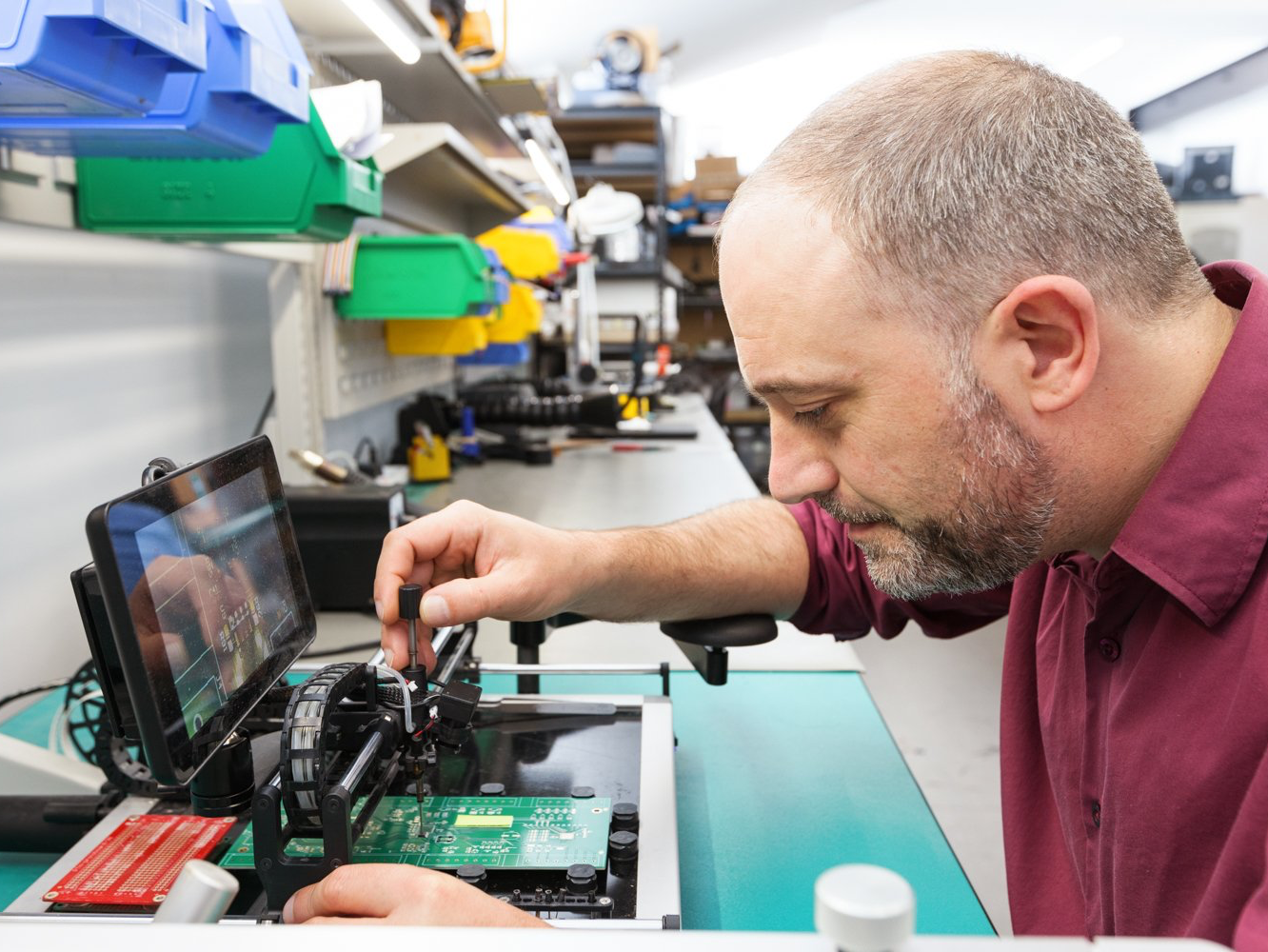

Our lab includes both our specialised electronics area. Complete with anti-static mats, soldering equipment, reflow ovens and diagnostics instrumentation, we also have a dedicated mechanical and materials section, which contains essential tools and our 3D printer.

Beta Solutions have the in-house resources to undertake rapid prototyping and fast, low volume PCB assembly for our clients. Our dedicated soldering equipment, including a precision reflow oven, allows us to solder intricate surface mount components to a high quality.

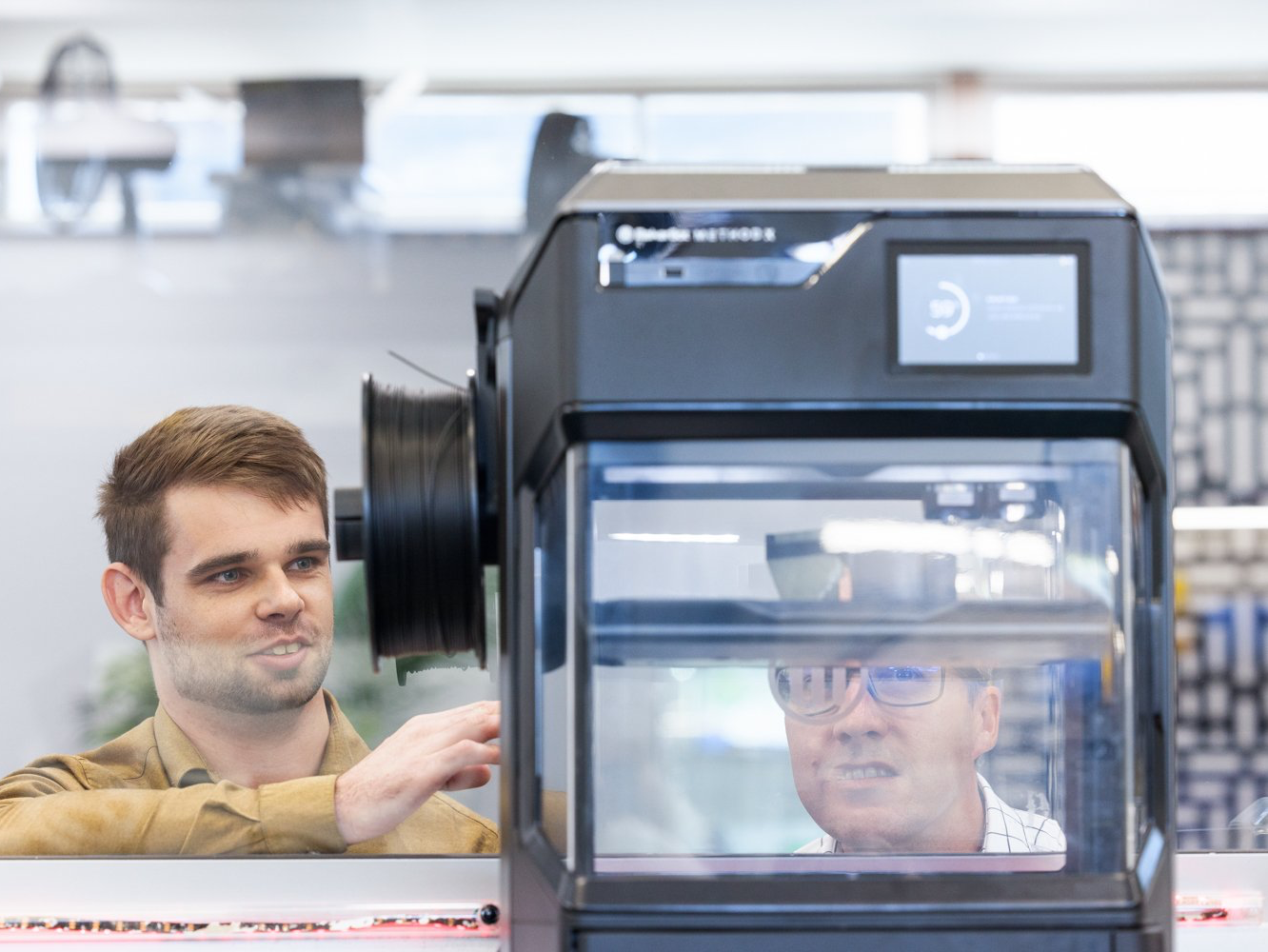

Our dedicated mechanical/materials design and assembly equipment, allow us to quickly prototype and validate new components. One indispensable tool is our 3D printer, which enables us to literally print a wide range of plastic components - such as electronic enclosures. In many cases, the relatively low cost nature, and fast turnaround time of 3D printing, allows a part to undergo numerous design optimisations before committing to expensive production tooling.

Whether you require pre-production units to get started, or a small production run without expensive setup costs or fully outsourced manufacturing, we have the experience and validated processes in place to ensure quality management and on-time delivery.

Beta Solutions promote a strong health and safety culture within the organisation. Our preventative measures include wearing safety glasses, lab coats, protective gloves and hearing protection where required. Residual current devices (RCDs) protect against high voltage electrical injures, while fume extraction systems ensure the air is kept clean. If anything should go wrong, our first aid trained staff are ready to respond.

Quality IT systems allow us to operate effectively and efficiently. We store all technical client data on secure local servers, which are backed up to an offsite server daily. Design and production files are all versioned for seamless tracking of design changes.

Two dedicated meeting rooms allow us to meet with our clients confidentially to discuss new ideas or projects. Modern technology also allows for telephone or video conferencing, so distance is not an obstacle to effective communication.

Within the open floor plan, there are quiet thinking spaces for collaboration and mindful moments, designed to inspire great ideas and effective solutions.

A designated social space with table tennis, dart board and a golf putting mat, helps foster our values of relationships and enjoyment. These areas allow colleagues to share ideas, work together and stimulate creative problem solving, for our clients’ projects.