Bluetooth - CapSense Switch

We were approached by NZ’s largest paint company, Resene Paints Ltd, with a view to help transform its idea into a commercial reality. Resene had a vision for a product which would enable users to control electrical devices, simply by touching specially painted surfaces. These surfaces would be coated in a newly developed touch sensitive conductive paint and connected to some intelligent electronics - responsible for monitoring the user’s touches and controlling the devices (e.g.: house lights). Resene chose Beta Solutions to develop its SmartTouch product - handling the entire electronics development process, from first concept to production.

Opportunity

Resene Paints Limited is New Zealand's largest paint manufacturing company. Established in 1946, Resene is today an international company with manufacturing and distribution operations in Australia and Fiji and local production plants in Lower Hutt, Upper Hutt and Auckland.

One of the reasons for Resene's success is its dedication towards innovation - with many inventions occurring throughout its long history. One recent such invention is a semi-conductive paint, which can be applied (using standard painting methods) to surfaces of all shapes and sizes. Resene envisioned that this paint could form part of a "touch sensitive" smart-device, whereby its customers could control various electrical devices in new and novel ways, simply by touching their walls!

To accomplish this goal, it required the outsourced development of some specialist electronics hardware, which would be responsible for (i) Interfacing with the touch sensitive paint (ii) Monitoring the user's touches and (iii) Controlling the customer's lights and/or other devices.

Resene chose Beta Solutions to be its development partner - handling the entire electronics development process - from first concept through to full product design and certification, and onto high volume production.

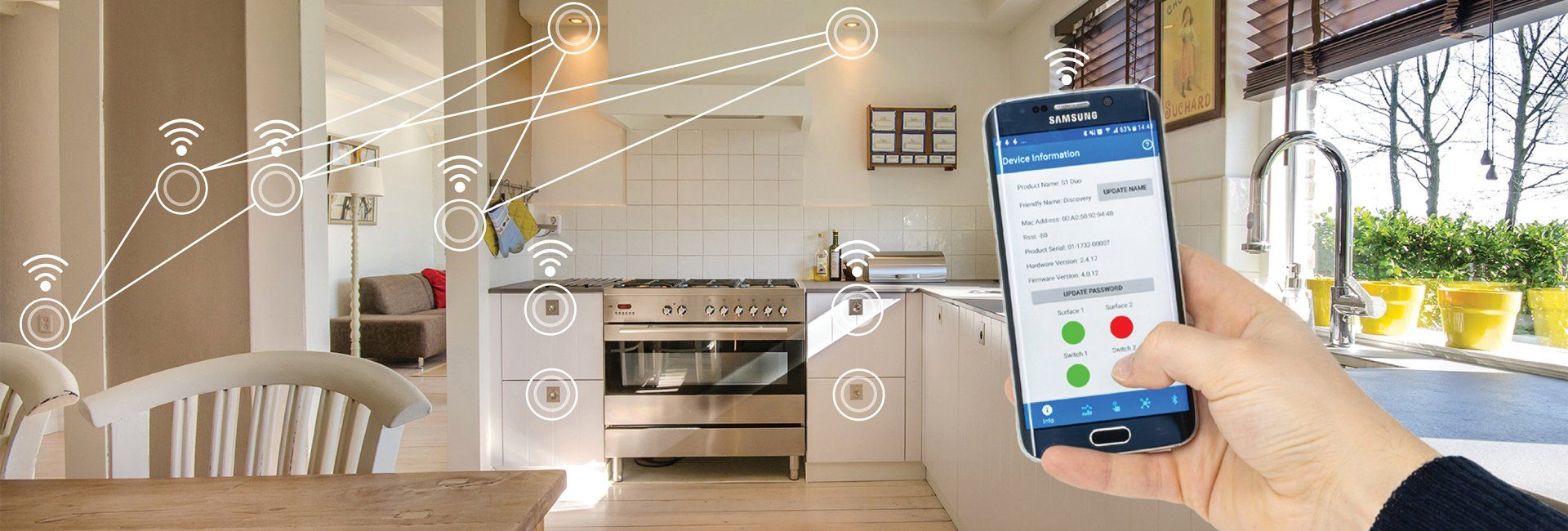

Figure 1: Resene had a vision for a product which would enable users to control electrical devices (e.g.: lights) simply by touching specially painted surfaces.

Solution

Resene had a vision of coating large surfaces with a new SmartTouch product. Naturally, the areas where paint is already applied make a good candidates. If an entire wall, or even an entire room could be coated in this paint, what could we do with it?

Undoubtedly, buildings/homes are continuing to get smarter and (especially with the Internet of Things (IoT) technology) are unlocking opportunities that were previously impossible. Therefore, it was apparent that by interfacing Resene's SmartTouch Paint with some intelligent bespoke electronics, an entire world of possibilities would arise. An entire surface/wall would be transformed into a large sensor!

This was the origin of the Smart Paint Switch idea, which would enable the On/Off control of mains powered electrical devices. At its most basic application, it would control the lights in a room and entirely replace the need for a physical light switch. By touching anywhere along a wall with specific touch patterns, users would be able to toggle the lights in a room from wherever they were!

Figure 2: With Resene's SmartTouch coating, entire surfaces can be transformed into sensors, which can be used to control house lighting and other devices.

Preliminary Design Phase

The first step in the project was to characterise the possibilities of Resene's new paint technology, and create a general product concept and architecture. Research was required to answer some pressing questions such as:

- What would be achievable with this new paint technology and equally what would not?

- How would we best "sense" the user's touch and what technology would be most appropriate?

- What Regulatory Compliance aspects would need to be considered?

- What would be the optimum way to connect the paint with the electronic controller?

- Conceptually, what would the product look like?

Through our research, it was discovered that capacitive sensing technology would be used to determine user interaction. Rapid proof-of-concepts were constructed to allow initial testing.

Through this, we were able to better understand the resistivity characteristics of the paint and define maximum usable areas.

Figure 3: Early stage proof-of-concepts, such as this one, were rapidly constructed to allow preliminary testing.

Detailed Design Phase

Following the early proof-of-concepts, there was sufficient confidence to

proceed to the Detailed Design Phase, whereby the actual final product would be developed.

Electronics Solution

Microcontroller and sensing circuitry:

The Smart Paint Switch contains a powerful Cypress microprocessor which acts as the brains of the device. The microcontroller was chosen due to Cypress' leading approach to integrated on-board capacitive sensing technology. Moreover, the micro is embedded in a module that contains certified wireless circuitry - simplifying the required regulatory compliance testing later in the project development life cycle.

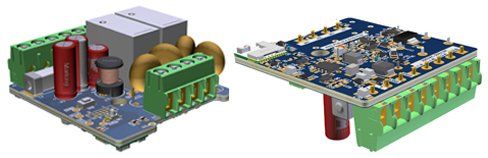

The electronics circuitry (schematics and PCB) was designed and modelled in CAD, which enabled real-time 3D visualisation of the product as it was constructed.

Figure 4: The Smart Paint Switch was modelled in CAD, enabling a 3D visualisation of the product.

Power Supply and 230V AC Mains integration:

The device was required to be designed to replace a function of a traditional mains light switch. With this came the challenges of keeping the design small enough to fit into existing wall switch installations. The power supply circuitry performs AC to DC conversion (rectification) and reduces the mains voltages - using energy efficient "switch mode power supplies" - to safe levels. The circuit also incorporates electrical isolation between the inputs and the power circuitry - which is good design practice and also required to meet regulatory safety standards.

Figure 5: The Smart Paint Switch PCB.

Wireless Communications:

The product has been designed to be used in a variety of applications, with each individual user in mind. The firmware is therefore highly configurable - allowing users to change various aspects such as tap patterns or other fine tuning and sensitivity settings. However, as the switch has been designed to sit behind a wall, users have restricted access to it. Peer-to-peer wireless communication was the solution to this restriction - enabling users to connect to any Smart Switch device through their phones without the need to be physically connected to it with cumbersome cables, etc.

Figure 6: An example of how the Smart Paint Switch can be wirelessly interconnected.

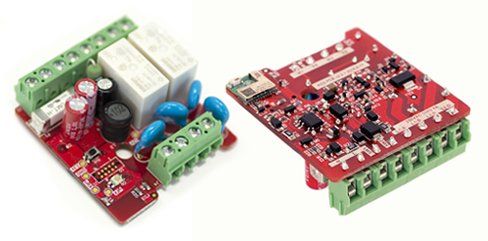

Inputs and Outputs:

The Smart Paint Switch has been designed with two sensor inputs and two outputs, i.e.: it can accept inputs from two independent SmartTouch coated surfaces, and also control two independent electrical devices. Combined with the programmable number of "User Taps", the device can be configured in a wide range of ways to meet the specific needs of the customer.

The outputs have been rigorously tested to switch an array of different electrical loads, including LED, Fluorescent and Incandescent lights.

Electro-Mechanical Solution

Enclosure:

The electronic circuit was housed in a plastic enclosure, which also served to electrically insulate the high voltage mains within. Beta Solutions designed the enclosure in CAD and iterated through several custom designs, through rapid prototyping made possible with 3D Printing. At each point the enclosure was "Designed for Manufacture", with the final iteration consisting of only two pieces, in order to keep the unit cost as low as possible for injection moulding.

Figure 7: Beta Solutions' Engineer (left) modelling the Smart Switch enclosure in 3D CAD (right).

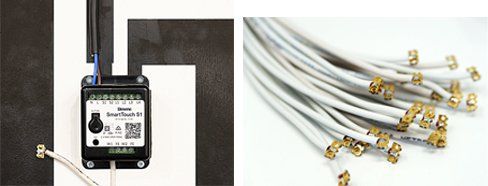

Wall Connection:

It is essential that the Smart Paint has a strong electrical connection with the Smart Switch electronics. Various options were considered and prototyped - including conductive adhesives and conductive tape. It was found the optimum solution consisted of a short double-insulated cable, running between the wall and the Smart Switch. This interlink cable made direct metal connection onto the wall - and was secured in place via two small metal tacks.

Figure 8: Illustration of how the interlink cable provides a robust way to connect the Smart Switch with the semi-conductive paint.

Firmware Solution

Algorithms:

Needless to say, large wall areas are bound to be randomly touched unintentionally at some point - for example, when cleaning or moving furniture etc. It was essential that the Smart Paint Switch was able to detect the difference between an intentional user touch versus an unintentional touch. Software algorithms were developed to look for specific touch patterns (a.k.a gestures) and to ignore everything else as random noise. For example: Two taps on the wall to turn one set of lights on/off - Three taps on the wall to turn a different set of lights on - Tap and hold to turn all lights off! The patterns are all user defined via the smartphone App (see below). These algorithms ensure that lights don't randomly turn on whenever someone (or Tiddles the cat) bumps into the touch sensitive wall.

Video 1: Resene SmartTouch paint system, turn on your lights with your wall paint.

Signal Processing:

In addition to the command gesture algorithms (above), the device incorporates advanced signal processing techniques to reduce electrical noise interference. The microprocessor executes software that includes digital filtering, edge detection and base line compensation - to ensure a high signal-to-noise ratio.

Figure 9: Beta Solutions' Engineer writing signal processing firmware for the Smart Switch.

Wireless Security:

An important part of any wireless device is security. Every Smart Paint Switch device can be encrypted with a unique network password. This network password allows units to identify each other and prevents any malicious user from being able to configure your devices.

Over the Air (OTA) Updates:

Just as it is possible for users to wirelessly update the software on their smart phone, the Smart Paint Switch was also designed with this feature in mind. The Smart Paint Switch contains a wireless bootloader, which allows users to update their devices via their smart phones (or a PC), which will ensure their devices are fully updated with the latest software.

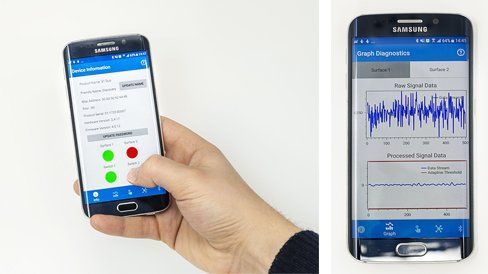

Smartphone App Solution

To facilitate the configuration of the Smart Paint Switch, a smartphone app was developed. Beta Solutions worked alongside Resene and a specialist 3rd party app developer to design a suitable application for both iOS and Android platforms. The smartphone app allows users to easily configure the device - setting parameters such as sensitivity, input/output mapping, and automatic on/off features.

Figure 10: A smartphone app was developed to enable users to easily configure their Smart Switch devices.

Validation and Testing Phase

It is essential that all electronics products, that are developed for the market, meet regulatory compliance standards. The design has been optimised through a few iterations of both firmware and hardware in order to meet adaptive client needs, all of which require consideration of various safety and radio certification criteria.

The Smart Paint Switch has been tested by independent laboratories to meet a range of EMC and Product safety tests including AS/NZS 60669.1, AS/NZS 60669.2.1, and AS/NZS 4268.

Figure 11: Being an electronic product, the Smart Switch was required to meet all required regulatory compliance standards - including Electromagnetic and Electrical Safety standards.

Production Phase

With the detailed design phase and validation and testing phases complete, the PCBs (and cabling) were moved into the high-volume production phase. This involved generating the final manufacturing source files for both the electronics and enclosure components, and working closely with our trusted ISO9001 certified manufacturing partners. All devices that passed through the production line were subject to strict quality control. Specifically, each unit was programmed and functionally tested and individually serial numbered prior to being shipped.

Figure 12: Resene SmartTouch PCB and final product.

Success

Beta Solutions has been privileged to partner with Resene in the development the Smart Paint Switch. A truly world-first product has been created, enabling a whole wall to be used as a sensor input to control mains powered devices. Furthermore, as a result of the research and development, Resene has been successful in protecting its intellectual property by way of patenting the concept of touch sensitive control systems for non-electronics display substrate surfaces.

Patent collaborative development: "Touch sensitive control system for non-electronic display substrate surfaces" [1]

Resene SmartTouch is available in stores and has featured on TVNZ’s “Homegrown” and TV3’s “The Block 2019”. You can read all about how the paint was used as a design element and how it replaced the need for light switches here.

Video 2: A 3D model of the Resene Smart Paint Switch.

References

- TOUCH SENSITIVE CONTROL SYSTEM FOR NON-ELECTRONIC DISPLAY SUBSTRATE SURFACES. Retrieved from : patentscope

* All the content in this article, including imagery, has been approved by our client for publication on this website.